Nyob rau hauv xyoo tas los no, muaj kev xav tau ntau ntxivhloov tau pob tshabcov yeeb yaj kiab uas tuaj yeem khoov lossis molded rau hauv cov duab sib txawv kom tau raws li ntau yam kev lag luam thiab kev xav tau. Cov yeeb yaj kiab no tau pom cov ntawv thov hauv kev lag luam xws li cov khoom siv hluav taws xob, cov khoom siv hluav taws xob, cov khoom siv hnub ci, thiab cov ntim ntse, thiab lwm yam. Lub peev xwm ntawm cov yeeb yaj kiab no los khoov yam tsis poob lawv qhov kev pom tseeb yog qhov tseem ceeb rau lawv txoj kev vam meej hauv cov ntawv thov no. Tab sis yuav ua li cas raws nraim li cov yeeb yaj kiab no ua tau zoo li no?

Txhawm rau teb cov lus nug no, peb yuav tsum delve rau hauv qhov muaj pes tsawg leeg thiab tsim cov txheej txheem ntawm cov yeeb yaj kiab no. Cov yeeb yaj kiab pob tshab feem ntau yog tsim los ntawm cov khoom siv polymers, uas yog cov hlua ntev ntawm kev rov ua dua molecular units. Kev xaiv ntawm cov khoom siv polymer ua lub luag haujlwm tseem ceeb hauv kev txiav txim siab qhov yooj yim thiab pob tshab ntawm zaj duab xis. Qee cov ntaub ntawv polymer uas siv rau cov yeeb yaj kiab yooj yim muaj xws li polyethylene terephthalate (PET), polyethylene naphthalate (PEN), thiab polyimide (PI).

Cov ntaub ntawv polymer no muaj cov khoom siv kho tshuab zoo heev, xws li lub zog tensile siab thiab kev ruaj ntseg zoo, thaum tseem tuav lawv cov pob tshab. Cov chains ntawm polymer molecules yog nruj nreem ntim thiab muab cov qauv muaj zog thiab zoo ib yam rau zaj duab xis. Qhov kev ncaj ncees ntawm cov qauv no tso cai rau cov yeeb yaj kiab tiv thaiv kev khoov thiab molding yam tsis muaj kev tawg lossis poob pob tshab.

Ntxiv rau qhov kev xaiv ntawm cov khoom siv polymer, cov txheej txheem tsim khoom kuj tseem ua rau kev hloov pauv ntawm cov yeeb yaj kiab. Cov yeeb yaj kiab feem ntau yog tsim los ntawm kev sib xyaw ua ke ntawm cov txheej txheem extrusion thiab stretching. Thaum lub sij hawm extrusion txheej txheem, cov khoom siv polymer yog yaj thiab yuam los ntawm qhov qhib me me hu ua tuag, uas ua rau hauv ib daim ntawv nyias. Daim ntawv no yog ces txias thiab solidified los ua zaj duab xis.

Tom qab cov txheej txheem extrusion, zaj duab xis yuav dhau los ua ib kauj ruam ntxiv los txhim kho nws qhov yooj. Stretching yuav rub cov zaj duab xis nyob rau hauv ob qho tib si perpendicular cov lus qhia ib txhij, uas elongates lub polymer chains thiab aligns lawv nyob rau hauv ib tug tshwj xeeb kev taw qhia. Cov txheej txheem ncab no qhia txog kev ntxhov siab hauv zaj duab xis, ua rau nws yooj yim rau khoov thiab pwm yam tsis tau poob nws cov pob tshab. Lub degree ntawm stretching thiab cov kev taw qhia ntawm stretching tuaj yeem hloov kho kom ua tiav qhov xav tau yooj yim hauv zaj duab xis.

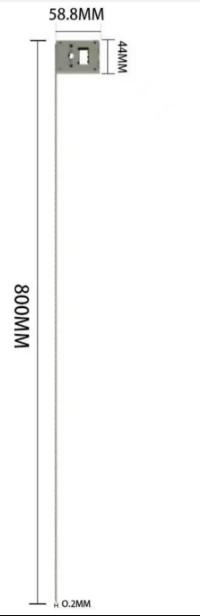

Lwm yam uas cuam tshuam rau kev khoov muaj peev xwm ntawmflexible pob tshab zaj duab xisyog lawv thickness. Cov yeeb yaj kiab thinner zoo li hloov tau yooj yim dua li cov tuab tuab vim lawv txo qis tsis kam khoov. Txawm li cas los xij, muaj kev lag luam tawm ntawm thickness thiab mechanical zog. Cov yeeb yaj kiab thinner tuaj yeem ua rau tawg lossis tawg, tshwj xeeb tshaj yog tias raug mob hnyav. Yog li ntawd, manufacturers yuav tsum optimize lub thickness ntawm cov zaj duab xis raws li ib tug tshwj xeeb daim ntawv thov.

Sib nrug los ntawm cov khoom siv kho tshuab thiab cov txheej txheem tsim khoom, lub pob tshab ntawm zaj duab xis kuj nyob ntawm nws cov yam ntxwv saum npoo. Thaum lub teeb cuam tshuam nrog zaj duab xis saum npoo, nws tuaj yeem cuam tshuam, xa mus, lossis nqus tau. Txhawm rau ua kom pom tseeb, cov yeeb yaj kiab feem ntau yog coated nrog nyias txheej ntawm cov ntaub ntawv pob tshab, xws li indium tin oxide (ITO) lossis nyiaj nanoparticles, uas yuav pab txo qis kev xav thiab txhim kho lub teeb kis. Cov coatings no xyuas kom meej tias cov zaj duab xis tseem pob tshab txawm tias thaum khoov los yog molded.

Ntxiv nrog rau lawv qhov yooj yim thiab pob tshab, cov yeeb yaj kiab yooj yim pob tshab kuj muaj ntau yam zoo dua li cov ntaub ntawv nruj. Lawv qhov hnyav hnyav ua rau lawv zoo tagnrho rau cov ntawv thov uas txo qhov hnyav yog qhov tseem ceeb, xws li hauv cov khoom siv hluav taws xob. Ntxiv mus, lawv lub peev xwm ua tau raws li qhov chaw nkhaus ua rau tsim cov khoom siv tshiab thiab txuag chaw. Piv txwv li,flexible pob tshab zaj duab xisyog siv nyob rau hauv cov duab nkhaus, uas muab ib tug ntau immersive saib kev.

Qhov kev thov nce ntxiv rauflexible pob tshab zaj duab xistau ua kom muaj kev tshawb fawb thiab kev loj hlob hauv daim teb no, nrog rau cov kws tshawb fawb thiab cov kws tsim khoom siv zog los txhim kho lawv cov khoom thiab nthuav lawv cov ntawv thov. Lawv tab tom ua haujlwm los tsim cov ntaub ntawv polymer tshiab nrog kev txhim kho yooj yim thiab pob tshab, nrog rau kev tshawb nrhiav cov txheej txheem tsim tshiab kom ua tiav cov nqi tsim khoom. Raws li qhov tshwm sim ntawm cov kev siv zog no, yav tom ntej zoo li cog lus rauflexible pob tshab zaj duab xis, thiab peb tuaj yeem cia siab tias yuav pom cov ntawv thov tshiab tshiab hauv ntau qhov kev lag luam.

Hauv kev xaus, qhov yooj yim ntawm cov yeeb yaj kiab pob tshab yog ua tiav los ntawm kev sib xyaw ua ke, suav nrog kev xaiv cov khoom siv polymer, cov txheej txheem tsim khoom, cov yeeb yaj kiab thickness, thiab nws cov yam ntxwv saum npoo. Cov ntaub ntawv polymer nrog cov khoom siv zoo heev tso cai rau cov yeeb yaj kiab tuaj yeem tiv thaiv kev khoov yam tsis tau poob pob tshab. Cov txheej txheem tsim khoom suav nrog extrusion thiab ncab kom ntxiv dag zog ntxiv. Coatings thiab nyias txheej yog siv los txo qhov kev xav thiab txhim kho lub teeb kis. Nrog kev tshawb fawb tsis tu ncua thiab kev txhim kho, yav tom ntej ntawmflexible pob tshab zaj duab xiszoo li ci ntsa iab, thiab lawv tau teeb tsa los hloov pauv kev lag luam thiab thev naus laus zis hauv ntau txoj hauv kev.

Post lub sij hawm: Sep-05-2023